Cement

Cement is a binding agent used in construction and is one of the key ingredients in concrete, which is widely used in the building industry. It is a fine powder that, when mixed with water, undergoes a chemical reaction known as hydration, resulting in a hard and durable material.

1. Raw Material Extraction

The main raw materials used in cement production are limestone, clay, shale, iron ore, and sand. These materials are quarried or mined from natural deposits.

2. Raw Material Preparation

The extracted raw materials are crushed and ground into a fine powder. The proportions of these materials are carefully controlled to achieve the desired chemical composition of the cement.

3. Raw Material Blending and Grinding

The powdered raw materials are blended in specific proportions to ensure a consistent mix. This blend is then fed into a rotating kiln where it is heated to high temperatures (up to 1450°C or 2642°F). The intense heat causes chemical reactions that transform the raw materials into clinker.

4. Clinker Production

The raw materials fuse together and form small, marble-sized nodules called clinker. The clinker is rapidly cooled using air or water quenching to maintain its desired properties.

5. Grinding of Clinker

The clinker is finely ground with gypsum (calcium sulfate) to produce cement powder. The addition of gypsum controls the setting time of the cement.

6. Packaging and Distribution

The final cement powder is stored in silos and then packaged into bags or bulk containers for transportation and distribution to construction sites.

Common uses of Cement

Concrete Production

Cement is the primary ingredient in concrete, which is used for a wide range of construction applications. It binds together aggregates (such as sand, gravel, or crushed stone) to create a solid, strong, and durable material. Concrete is used for foundations, floors, walls, bridges, highways, and various other structures.

Mortar Production

Cement is also used in the production of mortar, which is a paste-like material used for bonding bricks, stones, or other masonry units. Mortar provides structural integrity and strength to masonry walls, partitions, and other applications.

Stabilization and Grouting

Cement is used for soil stabilization, especially in road construction. It improves the strength and load-bearing capacity of weak soils. Cement-based grouts are used to fill gaps, voids, or cracks in concrete structures, providing reinforcement and preventing water penetration.

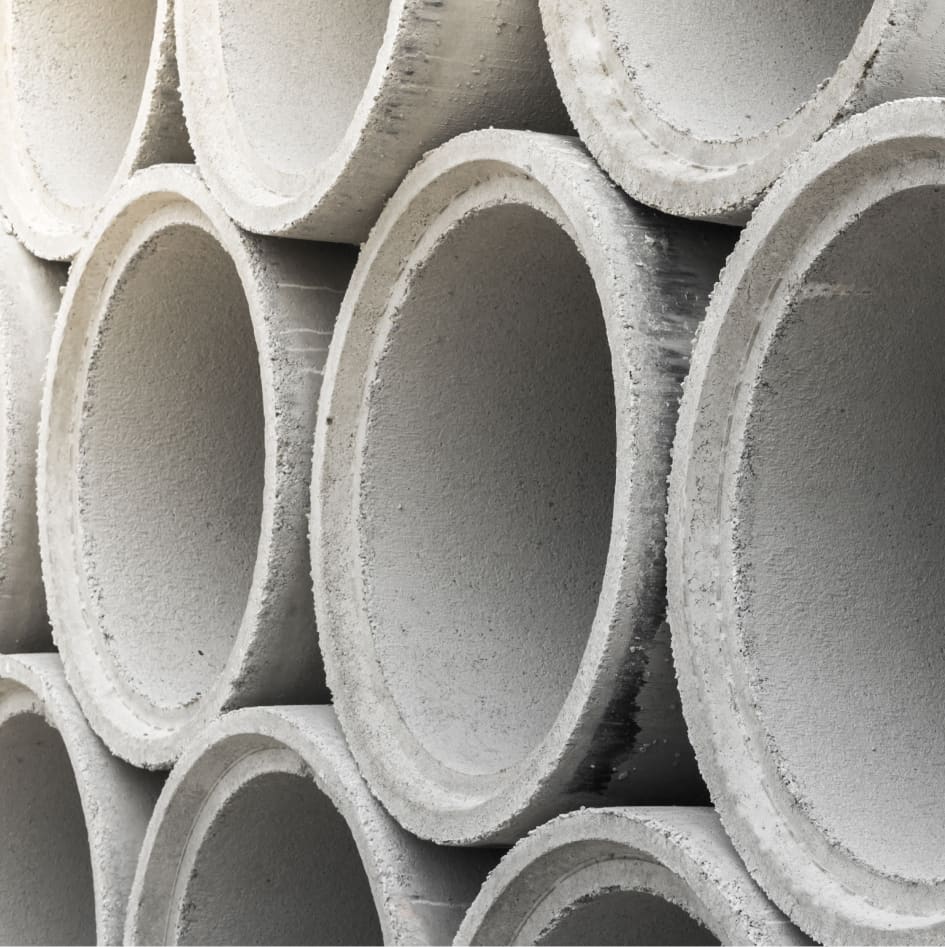

Precast Concrete Products

Cement is utilized in the manufacturing of precast concrete products such as pipes, poles, slabs, panels, and blocks. These products are cast in a controlled environment and then transported to construction sites for installation.

Surface Coatings and Finishes

Cement-based coatings, such as stucco or render, are applied to walls or exteriors to provide a protective and decorative finish. Cement-based materials are also used for waterproofing, sealing, and as a base for floor coverings.

Other Applications

Cement finds applications in various specialized fields, including the oil and gas industry, where it is used for well cementing and casing. It is also used in the production of cement-based composites, such as fiber cement boards, which are used as siding or roofing materials.

Cement is a fundamental building material that plays a crucial role in the construction industry. Its versatility, strength, and durability make it a key component in a wide range of applications, from simple residential structures to complex infrastructure projects.

Partner with CORE Supply for top-quality cement products backed by our extensive experience, trusted supplier relationships, and commitment to quality control. Contact us today to explore our cement products and experience the difference that CORE Supply can make for your next project.